In Oral Dissolving Film (ODF) development, product success starts with film quality. Uniform thickness, stable structure, and consistent API distribution are not just technical details — they are the foundation of a market-ready ODF product. A well-controlled film-making process is essential for turning a promising formulation into a reliable commercial product.

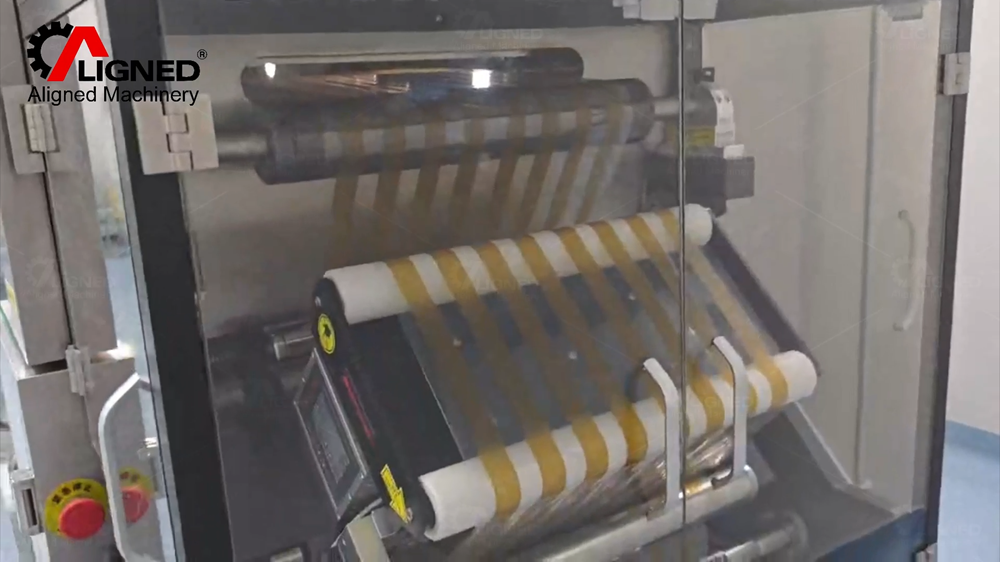

This ODF film making machine is designed to support stable and scalable production. With a theoretical speed of up to 1.5 meters per minute and a web width of 400 mm, it provides a balance between production efficiency and precise process control. This makes it suitable for manufacturers looking to move from development to larger-scale production while maintaining consistent product quality.

Stable casting is a key factor in achieving uniform film thickness. By ensuring smooth and controlled film formation, thickness variation is minimized across the entire web. Combined with carefully managed drying conditions, the process supports even API distribution throughout the film. As a result, each individual strip delivers a consistent dose — a critical requirement for product performance, patient safety, and regulatory confidence.

Controlled drying also plays a vital role in overall film quality. Precise temperature management allows solvents to evaporate evenly, reducing defects and supporting stable film structure. This improves downstream performance during cutting, packaging, and storage, helping manufacturers maintain consistency from batch to batch.

For ODF products, film consistency directly affects more than manufacturing efficiency. It influences scale-up success, batch reproducibility, and the ability to meet regulatory expectations. A stable and repeatable film-making process reduces development risks and supports smoother transitions from pilot production to commercial manufacturing.

At Aligned Machinery, we focus on providing ODF solutions that help manufacturers build confidence at every stage of production. By emphasizing process stability and quality control, our equipment supports reliable ODF manufacturing and long-term product success.

Whether the goal is faster scale-up, improved dose consistency, or smoother regulatory approval, investing in the right film-making process is a critical step toward bringing high-quality ODF products to market.

Aligned Machinery is a leading manufacturer of pharmaceutical machinery with over 20 years of experience. Our products are used by pharmaceutical companies worldwide. Recognized for quality, reliability, and compliance with international standards, we are committed to helping partners improve efficiency and achieve sustainable growth.

To learn more about our solutions or discuss your project needs, please reach us directly at info@aligned-machinery.com / +86 13967712128.

Post time: Jan-15-2026