Good Quality Vacuum Mixing Emulsifier - KFG-380 Automatic Oral thin film Slitting & Drying machine – Aligned

Good Quality Vacuum Mixing Emulsifier - KFG-380 Automatic Oral thin film Slitting & Drying machine – Aligned Detail:

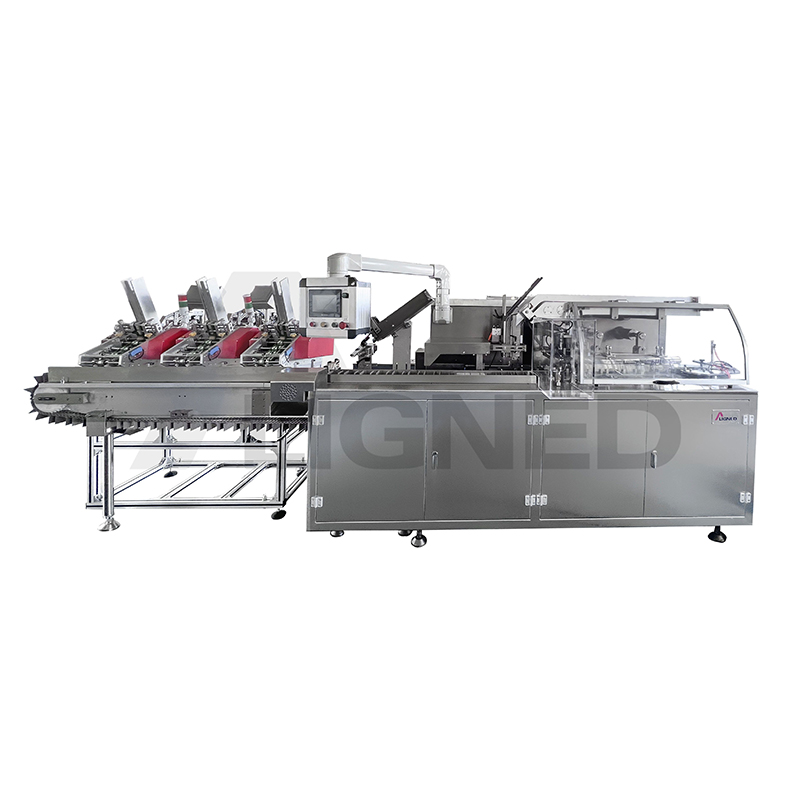

Sample diagram

Performance & features

The Oral film slitting machine used for an intermediate process equipment, works on film peeling from mylar carrier, film drying to keep uniform, slitting process and rewinding process, that ensures its proper adaption to next packing process.

In the ODF film production process, after the film is completed, it is affected by the production environment or other uncontrollable factors. We need to adjust and cut the film that has been produced, usually in terms of cutting size, adjusting humidity, lubricity and other conditions, so that the film can reach the stage of packaging, and make adjustments for the next step of packaging. Our equipment can be used to produce different types of film products.This equipment is an indispensable process in the film production process, ensuring the maximum use efficiency of the film.

The Oral film slitting machine new designed laser printing function. The Oral film slitting machine slitting funtion can equipp on the making machine. One Oral film slitting machine slitting funtion can support three units packing machine.

Usually, customers purchase equipment to produce drugs that require rapid absorption to treat various diseases. Such drugs require rapid absorption to achieve rapid problem solving and reduce patient symptoms.

After years of R&D and production, our equipment has continuously improved problems in experiments, solved equipment problems, improved equipment design problems, and provided strong technical guarantees for better service to customers.While the Aligned team provides you with high-quality equipment, it also provides you with efficient after-sales service, so you no longer have to worry about the future.

Believe in Aligned, believe in the power of faith!

Main Technical Parameters

| Project | Parameter |

| Production Capacity | Standard 0.002m-5m/min |

| Finished Film Width | 110-190 mm (Standard 380mm ) |

| Raw material width | ≦380mm |

| Total power | Three-phase five lines 220V 50/60Hz 1.5Kw |

| Air filter efficiency | 99.95% |

| Air pump volume flow | ≧0.40 m3/min |

| Packing material | Slitting composite film thickness (usually) 0.12mm |

| Overall dimensions ( L*W*H ) | 1930*1400* 950mm |

| Dividing material specifications | |

| Roll type packing material | Material Roll outer diameter |

| Thickness | 0.10-0.12 |

| Roll inner diameter | φ76-78mm |

| Material Roll outer diameter | φ350mm |

Product detail pictures:

Related Product Guide:

We have now our possess revenue group, design staff, technical crew, QC team and package group. We now have strict excellent regulate procedures for each process. Also, all of our workers are experienced in printing subject for Good Quality Vacuum Mixing Emulsifier - KFG-380 Automatic Oral thin film Slitting & Drying machine – Aligned , The product will supply to all over the world, such as: Australia, Belgium, Iran, We've got constantly insisted on the evolution of solutions, spent good funds and human resource in technological upgrading, and facilitate production improvement, meeting the wants of prospects from all countries and regions.

The supplier cooperation attitude is very good, encountered various problems, always willing to cooperate with us, to us as the real God.