OZM-340-4M Automatic Oral thin film making machine

Product Video

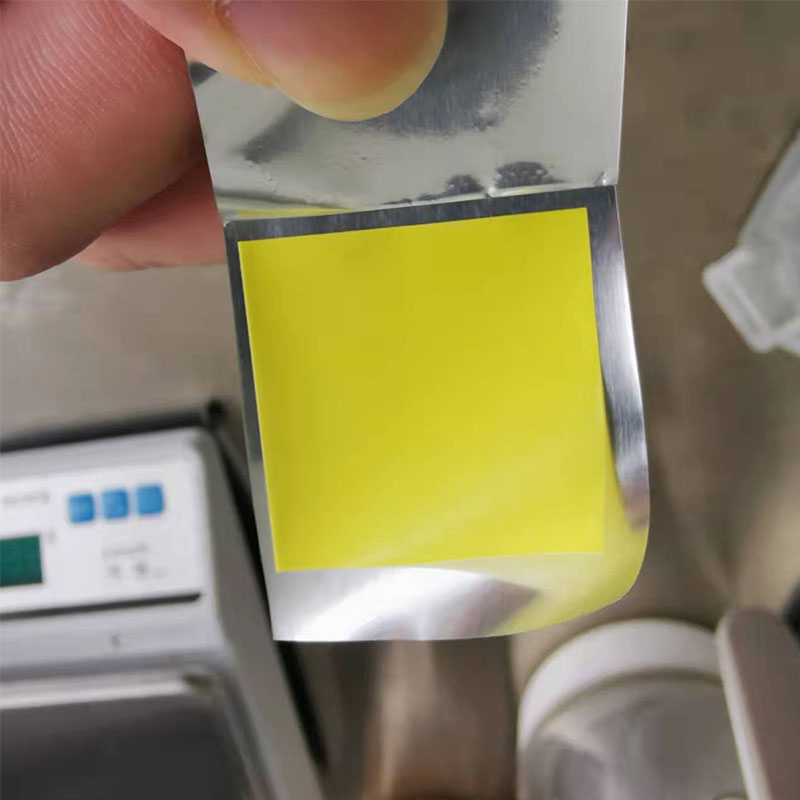

Sample diagram

Why choose Oral Strip?

- High dosing accuracy

- Quick dissolving,fast release

- No swallowing difficulty,high acceptance by elderly and children

- Small size convenient to carry

Working principle

The working principle of oral strip machine is evenly coated a layer of liquid material on the surface of the reel base roll. The solvent (moisture) is rapidly evaporated and dried through drying channel. And winding up after cooling (or composite with another material). Then, get the final products of the film (composite film).

Performance & features

1. It is suitable for the coating compound production of paper, film and metal film. The power system of the whole machine adopts the servo drive speed regulation system. Unwinding adopts magnetic powder brake tension control.

2. It adopts the main body plus accessory module structure, and each module can be disassembled and installed separately. The installation is positioned by cylindrical pins and fastened by screws, which is easy to assemble.

3. The equipment has automatic working length record and speed display.

4. The drying oven is divided into independent partitions, with functions such as independent automatic control of temperature, humidity, and concentration to ensure efficient and high-quality production.

5. The lower transmission area and the upper operation area of the equipment are completely sealed and isolated by stainless steel plates, which avoids cross-contamination between the two areas when the equipment is working, and is easier to clean.

6. All parts in contact with materials, including pressure rollers and drying tunnels, are made of stainless steel and non-toxic materials, which meet the requirements and specifications of "GMP". All electrical components, wiring and operating schemes comply with "UL" safety standards.

7. The emergency stop safety device of the equipment improves the safety of the operator during debugging and mold change.

8. It has a one-stop assembly line of unwinding, coating, drying and winding, with smooth process and intuitive production process.

9. The switchboard adopts a split structure, the drying area can be customized and lengthened, and the operation is smoother.

Technical Parameters

| Items | Parameters |

| Model | OZM-340-4M |

| Max casting width | 360mm |

| Roll width of film | 400mm |

| Running Speed | 0.1m-1.5m/min (depends on formula and process technology) |

| Unwinding diameter | ≤φ350mm |

| Winding diameter | ≤350mm |

| Method of heat & dry | Heating by external stainless steel heater, hot air circulation in centrifugal fan |

| Temperature control | 30~80℃±2℃ |

| Edge of reeling | ±3.0mm |

| Power | 16Kw |

| Overall dimension | L×W×H: 2980*1540*1900mm |